How a Persian Carpet Is Made

A Journey Into Art, Heritage, and Human Craft

Few creations in the world of art rival the timeless beauty of a Persian carpet. Each one is a piece of living history, an object where design, culture, and unmatched craftsmanship meet. Understanding how Persian carpets are made reveals a slow, precise, and deeply human process passed down through generations.

Below is a clear, engaging walk-through of how handmade rugs are made, from raw materials to the masterpieces admired in homes, galleries, and museums around the world.

Step 1: Selecting the Materials

Every Persian carpet begins with its fibers. The selection of wool, cotton, or silk determines not only the rug’s texture and durability, but also its character and long-term value. This foundational step is central to how Persian rugs are made.

Silk – The Pinnacle of Precision

Often called the queen of fibers, silk allows master weavers to achieve extremely fine knot counts and luminous detail. Sourced from silkworm cocoons, its smooth texture and natural sheen make it ideal for carpets of exceptional delicacy.

Cities such as Kashan, Qum, and Isfahan are renowned for silk masterpieces. Because silk is costly and more delicate, full-silk carpets are typically displayed as art or placed in low-traffic areas.

Cotton: The Foundation of Stability

Cotton forms the structural backbone of many Persian rugs, particularly in the warp and weft. Strong and flexible, it withstands high loom tension, providing stability and shape.

Its affordability and availability make cotton common in both everyday rugs and high-quality workshop pieces.

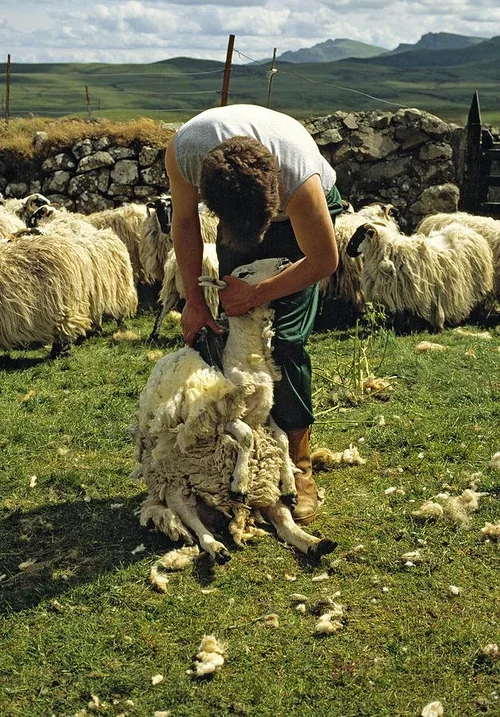

Wool – The Soul of Tradition

Wool has been the primary material in Persian rug weaving for centuries. Warm, resilient, and rich in natural lanolin, it is ideal for rugs intended to be used and lived with.

Wool quality varies by region. Tribal groups often use coarser wool, while cities such as Kerman are known for producing exceptionally soft, velvety fibers. Wool’s ability to absorb dyes gives Persian carpets their deep, enduring color

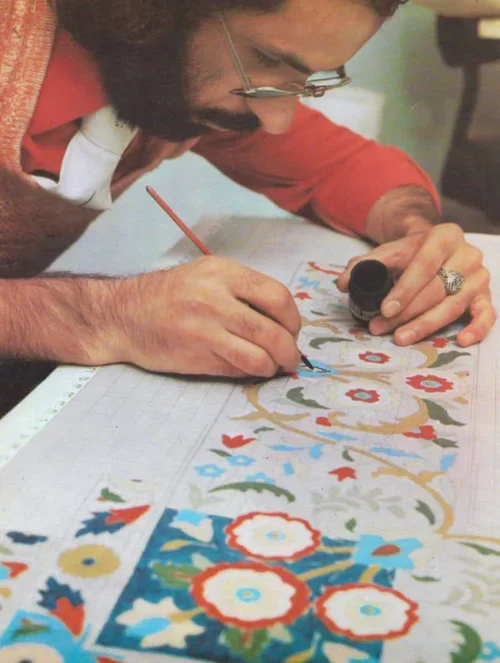

Step 3: Design & Planning

Before weaving begins, a detailed design plan, known as a cartoon, is created. This roadmap guides every knot and color transition.

Design inspiration often draws from centuries-old motifs, botanical forms, geometry, poetry, mythology, and architectural elements. This planning ensures that raw fibers are transformed into a cohesive and balanced work of art.

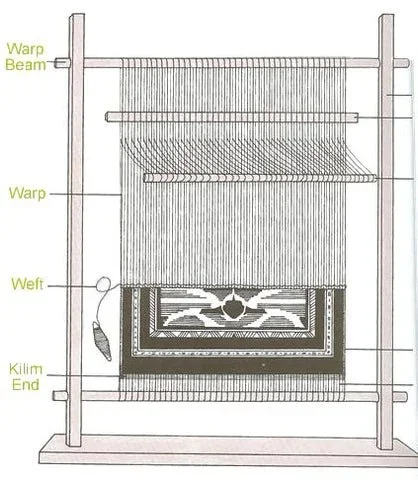

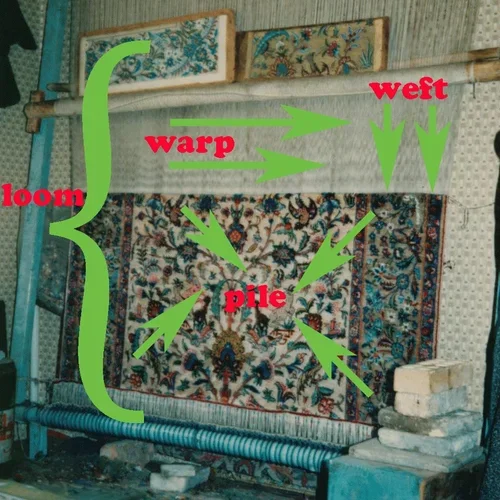

Step 4: Setting Up the Loom

The loom forms the structural framework of Persian rug weaving. Vertical warp threads are stretched tightly, creating the foundation onto which knots are tied.

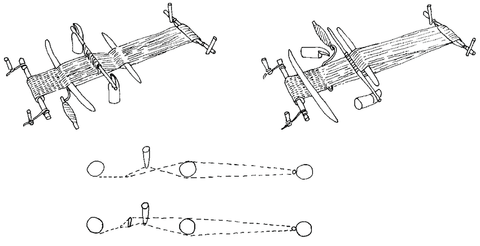

Early Nomadic Looms

Nomadic tribes traditionally used horizontal ground looms, portable structures designed to move with their lifestyle. Many village and tribal rugs admired today were created on these looms.

Vertical Looms, The Urban Revolution

As weaving developed in urban centers, vertical looms became standard.

Fixed vertical looms allowed for large, intricate carpets, while specialized looms enabled the weaving of longer formats.

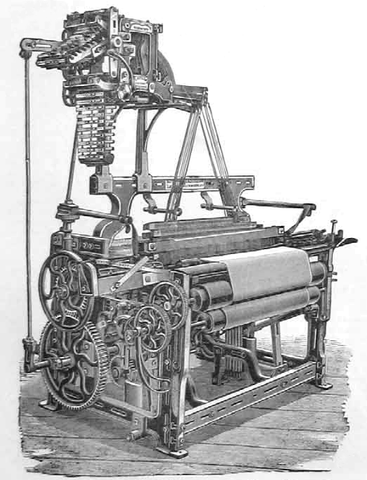

Industrial Looms

emerged in the 19th century, increasing production at the expense of the handmade character that defines true Persian carpets. Traditional handweaving remains the benchmark of authenticity.

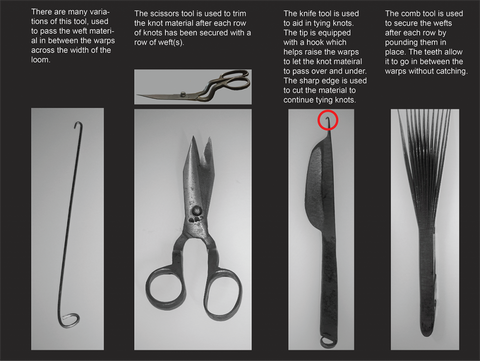

Traditional Tools

Persian weaving relies on tools refined over centuries, including knives for cutting yarn, beaters for tightening the weft, shuttles for thread, scissors for pile trimming, hooks for knotting, and spindles for spinning fibers.

Each tool contributes to the precision and artistry of the final product

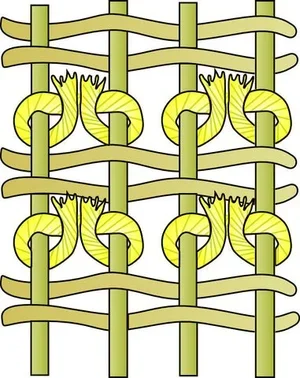

Step 5: Knotting the Pile

This is the heart of the process and central to how Persian carpets are made. Tens of thousands to millions of knots are tied by hand.

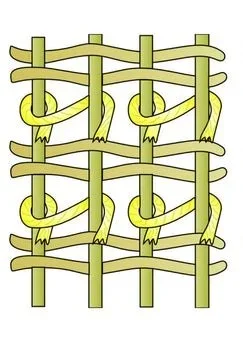

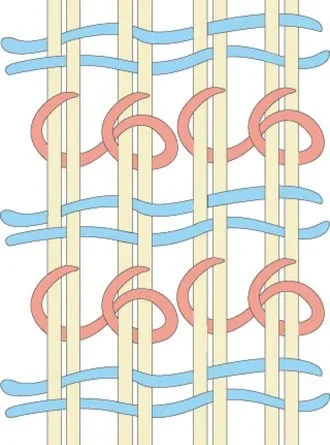

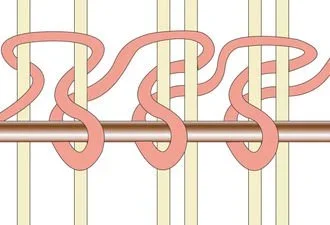

Primary Knot Types

The asymmetrical Persian knot and the symmetrical Turkish knot are the two most common, tied row by row to form the design and depth.

Additional Knot Variations

Jufti KnoT

introduced in the 20th century, speeds production but reduces density and durability.

Tibetan Knot

influenced by external traditions, creates looped rows that are later cut or left intact depending on the desired texture.

Weaving the Rows

Between each row of knots, weft threads are passed horizontally to secure the structure. Skilled weavers blend colors and tones with remarkable precision.

Finishing Touches

Once weaving is complete, edges are bound, the pile is trimmed, and the rug is washed and brushed to reveal its sheen. Hand clipping may refine details, bringing the design fully to life.

The Enduring Legacy

From Persian valleys to royal palaces, museums, and private collections around the world, Persian carpets have become symbols of heritage, artistry, and identity.

Each carpet reflects its geography, the culture of its people, and the patience and skill invested over months or years of work.

Understanding how Persian rugs are made deepens appreciation for their beauty and reminds us that these works are not simply woven, but created knot by knot with intention, knowledge, and care. They are not just floor coverings, but stories and legacies preserved in wool, cotton, and silk, meant to be admired, lived with, and passed down through generations.